CZ: DIAMONDS ARE BEING COUNTERFEITED | EN

Everybody more or less knows the cubic zirconium (CZ). To this day, it is the best imitation of a diamond. Precisions about this substitute for the eternal gem.

Forever, man has tried to copy diamond and find a substitute for it. As such, the most ancients are no doubt the white sapphires, colourless topaz, zircons or, more simply, glass. Strass represents the first revolution its name comes from the jeweller called Von Strass, who lived during the days of Louis XV It is a colourless lead glass, whose yoke was covered with a toxic mercury-tin mixture, as for the mirror, giving a shine comparable to the diamond's. Today this process is still used in fashion jewellery At the beginning of the 20th century, sapphire and synthetic spinel have come on the market. A little bit later, in 1955, strontium titanium, better known as fabulite, has been discovered. This synthetic stone, slightly milky, if offering colourful confetti. In 1968, its production reached 15 million carats. In 1972, however, the yag, discovered while carrying out research on the laser ray, Jumped ahead its production then reached 40 million carats.

The best substitute The cubic zirconium, called CZ - yet it goes by several different names cubic zirconia, diamonite, diamondite, diamond-Z, fianite, etc. - was born some time later, in 1976 It soon became known as the best substitute for diamonds and in 1980, its production exceeded 60 million carats. Today, the figures for the CZ production are unknown. In the beginning, the word cubic zirconium, had to be followed by the specification, 'synthetic'. Known to be resistant to very high temperatures - 2,000 degrees -, it had already been used in the composition of ceramics for industrial or scientific purposes.

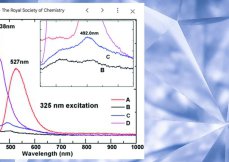

Cubic zirconium (Zro2) has to be stabilised with calcium, with yttrium or with small quantities of metallic oxides. Pure, it melts at very high temperatures, from 2,750 degrees. With the use of certain additives - indispensable to its cooling -, this temperature may be reduced. At the first stage, a monoclinic or tetragonal construction results from it. When it is overheated, at 1,100 degrees, the passage from monoclinic to tetragonal is final. At 2,000 degrees, zirconium becomes cubic.

The United States and Russia, straight away, became the biggest producers of raw material. Russia filed its patent in 1972 In the United States, the Ceres group also eventually filed one, after many controversies. As for the cutting centres, they are scattered all over the world. The most important ones are in Bangkok, in Korea, Jaipur or Sri Lanka. In the European centres, just like Idar Oberstein, cutting is more often than not fully automated.

|